Introduction to 3D printing with metal

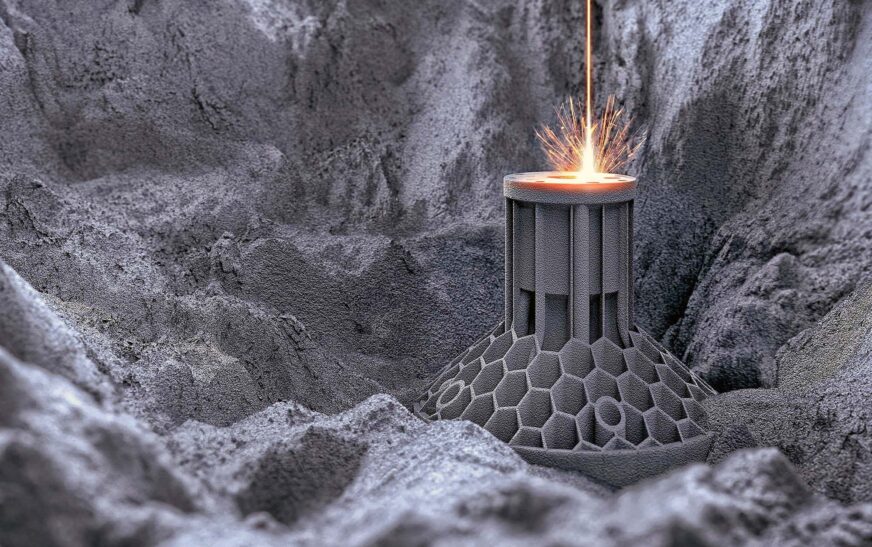

The world of manufacturing is undergoing a dramatic transformation, and at the heart of this revolution lies an innovative technology that’s capturing attention: metal 3D printing. Gone are the days when creating complex metal parts required extensive machining and long lead times. Today, with advanced techniques in additive manufacturing, businesses can design and produce intricate components faster than ever before.

Imagine being able to craft lightweight yet durable structures tailored precisely to your specifications—all while minimizing waste and reducing costs. Metal printing opens up exciting new possibilities across various industries, from aerospace to automotive. The future of manufacturing is here, and it’s made of metal! Let’s dive deeper into how this groundbreaking technology is reshaping our production landscape.

Advantages of using metal in 3D printing

Metal in 3D printing offers a range of advantages that set it apart from traditional manufacturing. One of the most significant benefits is the ability to create complex geometries. Intricate designs can be produced with ease, which would be difficult or impossible using conventional methods.

Another key advantage is material efficiency. Metal 3D printing generates less waste compared to subtractive processes, making it both cost-effective and environmentally friendly. This efficiency doesn’t compromise strength; printed metal parts often exhibit superior mechanical properties.

Speed is also a factor worth noting. Rapid prototyping and production capabilities mean companies can bring products to market faster than ever before. Customization becomes straightforward, allowing for tailored solutions that meet specific needs without extensive retooling.

Reduced assembly requirements streamline production further by enabling multi-part assemblies to be printed as single components, minimizing potential points of failure in finished products.

Current applications of 3D printed metal

3D printed metal is making waves across various industries. Aerospace stands at the forefront, utilizing this technology for lightweight components that enhance fuel efficiency. These parts are often complex and difficult to produce with traditional methods.

The automotive sector also benefits significantly. Manufacturers create prototypes and intricate designs that push the boundaries of engineering. Customization becomes feasible without extensive tooling costs.

Medical applications showcase remarkable potential as well. Surgeons now use 3D printed titanium implants tailored specifically to a patient’s anatomy, improving recovery outcomes.

In energy production, companies are printing parts for turbines and other machinery, optimizing performance while reducing waste materials.

From art to architecture, creativity knows no bounds; artists craft unique sculptures while architects design innovative structures using advanced techniques in metal printing. The versatility of metal 3D printing continues to reshape how we think about manufacturing processes today.

Impact on traditional manufacturing methods

3D printing with metal is shifting the landscape of traditional manufacturing. It introduces a level of design freedom that conventional methods simply cannot match. Complex geometries and intricate details can be produced in ways previously deemed impossible.

This technology reduces waste significantly. Traditional machining often involves cutting away excess material, whereas 3D printing builds objects layer by layer, using only what’s necessary.

Moreover, it accelerates production times. Quick prototyping allows companies to iterate designs faster than ever before. This agility enables manufacturers to respond rapidly to market demands.

The supply chain also sees transformation. With localized production capabilities, businesses can reduce shipping costs and times while minimizing their carbon footprint.

As these advancements unfold, traditional methods may need reevaluation or adaptation to stay competitive in this evolving landscape.

Challenges and limitations of 3D printing with metal

3D printing with metal is an exciting frontier, but it comes with its fair share of challenges. One significant hurdle is the high cost of equipment and materials. Specialized printers capable of handling metals can be prohibitively expensive for many businesses.

Additionally, there’s the issue of production speed. Metal 3D printing often takes longer than traditional methods. This slower pace can hinder large-scale manufacturing operations where time is critical.

Quality control also presents complications. Variations in temperature during printing can lead to defects or inconsistencies in the final product. Ensuring each piece meets stringent industry standards requires meticulous attention.

Post-processing demands additional resources and time. Components typically need machining or finishing touches before they are ready for use, adding complexity to the workflow and extending timelines significantly.

The future of metal 3D printing technology

The future of metal 3D printing technology is brimming with potential. As materials science advances, new alloys and composite metals are emerging. This will allow for even stronger and lighter components.

Innovative techniques like binder jetting and directed energy deposition continue to evolve. They promise greater speed and efficiency in the printing process. The reduction in production time could change the landscape of manufacturing entirely.

Moreover, automation is set to play a significant role. Integrating AI and machine learning can optimize designs before they’re printed, enhancing precision while minimizing waste.

Sustainability also beckons on the horizon. With better recycling methods for metal powders, we may see a decrease in environmental impact.

As industries adopt these technologies at scale, traditional barriers will start to dissolve, paving the way for unparalleled creativity and customization in design processes across sectors.

Conclusion

3D printing with metal is not just a trend; it’s a transformative force in the manufacturing landscape. As technology advances, we are witnessing a shift that redefines how products are conceived and produced. The advantages of using metal in this process—like design flexibility and reduced waste—set the stage for innovation across industries.

Current applications highlight its versatility, from aerospace components to intricate medical devices. These examples illustrate how 3D printed metal can enhance performance while cutting costs. Traditional manufacturing methods are being challenged as companies explore this advanced approach, encouraging efficiency without compromising quality.

However, challenges remain. Issues such as material limitations and technical expertise need addressing for broader adoption. Yet, ongoing research offers promising solutions that could pave the way for more widespread use.

Looking ahead, the future of metal 3D printing promises further advancements that will likely lead to even greater capabilities and efficiencies within various sectors. This evolution signifies not only an improvement in processes but also a fundamental change in our understanding of manufacturing itself.

The journey into 3D printing with metal has just begun, but its implications could very well revolutionize how we manufacture goods moving forward.