Introduction to Self-Healing Materials

Imagine a world where materials can repair themselves when damaged, just like our skin heals from cuts. This concept isn’t merely a futuristic fantasy; it’s becoming a reality with the advent of self-healing materials. These innovative substances have the remarkable ability to autonomously mend damage, ensuring longevity and durability in various applications. From everyday items we use to groundbreaking technologies, self-healing materials are changing how we think about construction and design.

With an increasing demand for sustainability and efficiency, researchers are exploring these incredible materials across multiple industries. They promise not only to enhance product lifespan but also to reduce waste—a win-win for consumers and the environment alike. So let’s dive deeper into this fascinating realm of self-repairing innovation!

How do Self-Healing Materials Work?

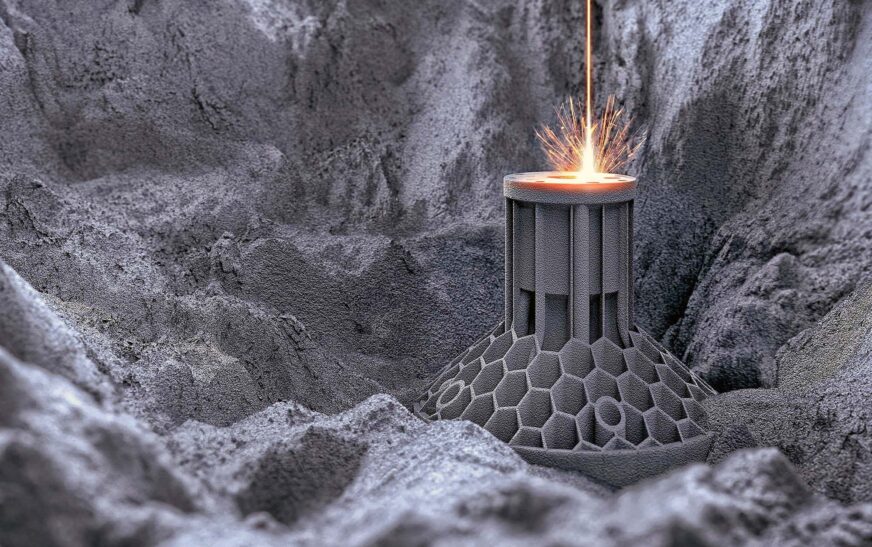

Self-healing materials possess an intriguing ability to repair themselves when damaged. This remarkable feature stems from their unique composition and design. Often, these materials are embedded with microcapsules filled with healing agents.

When a crack or scratch occurs, the microcapsules break open, releasing the healing agent into the damaged area. This substance reacts chemically to form bonds that restore structural integrity.

Some self-healing materials utilize reversible chemical reactions instead of capsules. These allow them to reconfigure at the molecular level after damage, effectively “healing” without additional materials.

Another fascinating approach involves polymer networks that can physically realign after deformation. The flexibility in their structure enables them to return to their original shape over time.

This innovative technology offers numerous possibilities across various industries by minimizing waste and extending the lifespan of products significantly.

Types of Self-Healing Materials

Self-healing materials come in various forms, each with distinct mechanisms that enable them to repair themselves when damaged. One popular type is polymer-based self-healing materials. These polymers often contain microcapsules or vascular networks filled with healing agents. When the material sustains damage, these capsules rupture, releasing the healing agent and triggering a chemical reaction that restores integrity.

Another fascinating category includes metal alloys enhanced with self-healing properties. These materials use specific additives that respond to stress fractures by forming new metallic bonds at the site of damage.

Ceramic composites also show promise in this field. By incorporating certain nanomaterials, they can regenerate their structure after cracking under pressure.

Each type brings unique advantages across industries, paving the way for more resilient products and structures in our everyday lives.

Applications and Benefits of Self-Healing Materials

Self-healing materials are revolutionizing various industries, from construction to electronics. In infrastructure, these materials can repair cracks and damage autonomously, extending the lifespan of buildings and roads without constant maintenance.

In consumer products, self-healing coatings protect devices like smartphones from scratches. Imagine a phone case that mends itself after a drop or scratch—it enhances durability and user experience significantly.

Healthcare also benefits immensely. Self-healing polymers can be used in wound dressings that respond to tears by sealing them automatically, speeding up recovery times for patients.

Another exciting application is in automotive manufacturing. Cars made with self-repairing components could reduce repair costs and increase safety over time by addressing minor damages before they escalate into serious issues.

These innovations not only enhance functionality but also cut down on material waste and resource consumption—an essential advantage in today’s environmentally conscious world.

The Future of Self-Healing Materials

The future of self-healing materials is brimming with potential. As research accelerates, these innovative substances promise to transform how we think about repair and durability.

Imagine structures that can automatically mend cracks or wear without human intervention. This could drastically reduce maintenance costs in construction and manufacturing.

Advancements in nanotechnology may lead to even more sophisticated self-repair mechanisms. These materials might react intelligently to damage, ensuring integrity over time.

Moreover, industries like automotive and aerospace are keenly exploring applications. Vehicles that can heal minor scratches or dents would enhance longevity and aesthetics.

Sustainability also plays a role in their development. Self-healing materials could minimize waste by extending the lifespan of products we use daily.

As scientists continue experimenting with new compounds and interactions, the possibilities seem endless. The next generation of self-healing technologies will likely redefine our relationship with material goods altogether.

Challenges and Limitations

Despite the promise of self-healing materials, several challenges hinder their widespread adoption. One major issue is the complexity of integrating these materials into existing manufacturing processes. Engineers often find themselves navigating uncharted territory when trying to blend conventional and advanced materials.

Moreover, the cost associated with developing and producing self-healing substances can be prohibitive. For many industries, particularly construction or automotive sectors, budget constraints limit experimentation with innovative materials.

Durability poses another concern. While some self-healing methods effectively repair minor damage, they may not withstand extreme conditions or repeated stress over time.

Environmental factors also play a role in limiting efficacy. Some healing mechanisms depend on specific temperatures or moisture levels that aren’t always present in real-world applications.

Addressing these hurdles requires ongoing research and collaboration across multiple disciplines. Only then can we unlock the full potential of self-healing technologies.

Conclusion

Self-healing materials represent a fascinating frontier in material science. They offer innovative solutions to some of the most challenging problems we face, from reducing waste in manufacturing to enhancing the durability of everyday products. The ability of these materials to repair themselves when damaged opens doors to new applications across various industries.

As technology continues to evolve, so too will self-healing methods and materials. Research is ongoing, and breakthroughs could lead us toward even more advanced self-repair capabilities that mimic biological processes more effectively.

However, some challenges remain. Costs for production and integration into existing systems can be prohibitive at times. Additionally, understanding how these materials behave over long periods under different conditions is essential for broader adoption.

Despite these hurdles, the promise they hold is undeniable. As we explore further innovations in this field, it’s clear that self-healing materials will play an increasingly vital role in our future—redefining our approach to design and sustainability while enhancing performance across numerous applications.