Introduction to Soft Robotics

Imagine a world where robots can bend, stretch, and adapt to their surroundings just like living organisms. This is not science fiction; it’s the exciting realm of soft robotics. Unlike traditional robots with rigid bodies made of metal and plastic, soft robots are designed with flexible structures that allow them to move in ways we never thought possible. They mimic the dexterity of nature, using materials such as silicone or rubber to create adaptable machines that can perform delicate tasks.

As industries evolve and technology advances, the demand for more versatile solutions grows. Soft robotics holds promise not only for manufacturing but also for healthcare, agriculture, and beyond. Let’s dive deeper into what makes these innovative creations unique and explore how they are reshaping our understanding of automation in various fields.

What Makes Soft Robotics Different from Traditional Robotics?

Soft robotics stands apart from traditional robotics primarily due to its material composition. While conventional robots often rely on rigid metals and plastics, soft robots utilize flexible materials like silicone and rubber. This adaptability allows for safe interaction with human environments.

Another key difference lies in mobility. Traditional robots may struggle with complex terrains, whereas soft structures can deform to navigate obstacles smoothly. Their gentle touch makes them suitable for delicate tasks that require precision without the risk of damage.

Moreover, control mechanisms vary significantly between the two fields. Soft robotics employs unique actuation methods such as pneumatic or hydraulic systems, enabling versatile movements that mimic biological organisms.

In essence, it’s this combination of flexibility, safety, and innovative technology that sets soft robotics apart from their more traditional counterparts in the robotic landscape.

The Advantages of Soft Robotics

Soft robotics offers a range of advantages that set it apart from traditional designs. One significant benefit is safety. With their flexible structures, these robots can interact with humans without the risk of injury, making them ideal for collaborative environments.

Their adaptability is another strong point. Soft robots can conform to various shapes and navigate through tight spaces effortlessly. This flexibility allows them to perform tasks in unpredictable settings.

Another advantage lies in their lightweight materials. These contribute to energy efficiency and reduce operational costs over time.

Moreover, soft robotics often involves simpler control mechanisms compared to rigid counterparts, decreasing complexity in design and programming.

These unique qualities open doors for innovative applications across industries like healthcare, agriculture, and manufacturing, transforming how we think about automation.

Applications of Soft Robotics in Various Industries

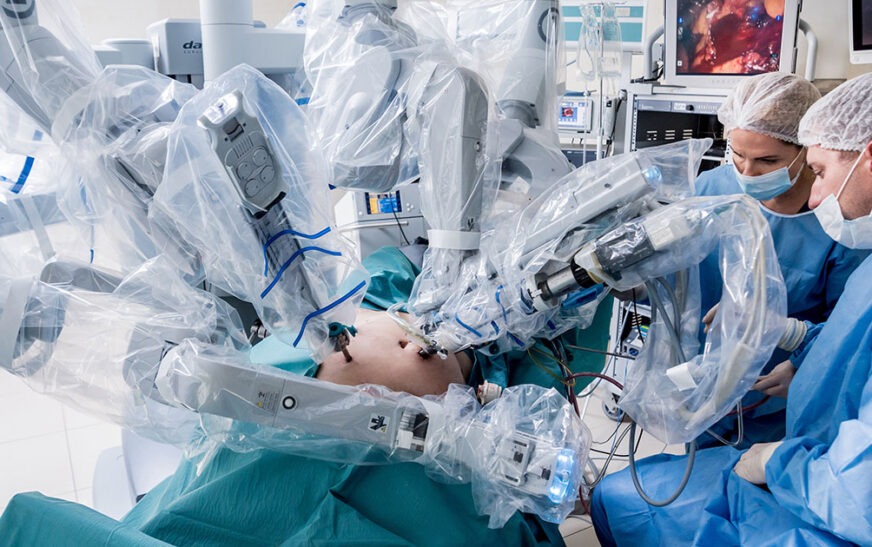

Soft robotics is making waves in a variety of industries, transforming the way tasks are performed. In healthcare, soft robots assist in delicate surgeries and rehabilitation therapies. Their flexible structures allow them to navigate around sensitive environments without causing harm.

In agriculture, these adaptive machines handle fragile crops with care. With their gentle touch, they can pick fruits or vegetables without bruising them. This capability boosts efficiency and minimizes waste.

The manufacturing sector also benefits from soft robotics. These robots work alongside humans on assembly lines, adapting seamlessly to different tasks. Their pliable nature allows for safer interactions with workers.

Exploring the world of logistics reveals another exciting application—soft robotic grippers that manage packages of various shapes and sizes efficiently. The innovation doesn’t stop here; each industry continues to discover new ways to incorporate this technology into everyday operations.

Examples of Successful Soft Robotics Projects

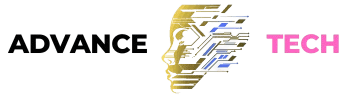

One remarkable example of soft robotics comes from researchers at Harvard University. They developed a soft robotic gripper inspired by the way an octopus captures its prey. This flexible design allows it to handle delicate objects without causing damage, showcasing the potential of adaptive structures.

Another innovative project is the Soft Robotics Toolkit, which provides resources for creating custom soft robots. It encourages creativity and experimentation, making it accessible for both professionals and hobbyists alike.

In agriculture, companies like Octinion have introduced robots that can gently pick strawberries. These machines utilize soft touch technology to ensure ripe fruits are harvested without bruising them.

The medical field has also seen advancements with devices designed for minimally invasive surgeries. These flexible tools navigate complex pathways within the human body while maintaining precision and safety.

Limitations and Challenges of Soft Robotics

Soft robotics, despite its many advantages, faces significant limitations. One major challenge lies in material durability. The flexibility that makes these robots so adaptable can also lead to wear and tear over time.

Another concern is control systems. Soft robots require advanced algorithms to navigate their environments effectively. Developing these sophisticated systems remains a hurdle for researchers.

Power supply poses additional difficulties. Many soft structures rely on pneumatic or hydraulic systems, which can be bulky and limit mobility. Finding lightweight power sources is essential for improving efficiency.

Furthermore, the manufacturing process of soft materials often lacks standardization. This variability can affect performance consistency across different applications.

Public perception plays a role in adoption rates. As people become accustomed to traditional rigid robots, they may remain skeptical about the reliability of flexible alternatives in critical tasks.

These challenges present opportunities for innovation as the field evolves and matures.

Future Potential of Soft Robotics

The future potential of soft robotics is vast and exciting. As technology evolves, these adaptable systems will increasingly integrate into our daily lives. Imagine robots that can navigate complex environments with ease, thanks to their flexible structures.

Advancements in materials science are paving the way for softer, more resilient robots. These innovations will enable machines to operate safely alongside humans without causing harm. This opens doors for collaborative tasks across various sectors.

Moreover, as industries seek sustainable solutions, soft robotics offers an eco-friendly alternative. Their lightweight designs require less energy and could lead to greener production methods.

Research is also focusing on bio-inspired designs. By mimicking nature’s adaptive strategies, engineers can create robots capable of performing intricate operations in unpredictable settings. The synergy between biology and technology holds promise for groundbreaking applications we have yet to imagine.

Conclusion

Soft robotics is changing the landscape of technology. By focusing on flexible structures and adaptive capabilities, this field offers solutions that traditional robots simply cannot. The advantages are clear: enhanced safety, versatility in applications, and the ability to navigate complex environments with ease.

Industries like healthcare, agriculture, and manufacturing are already reaping the benefits of these innovative robots. With successful projects showcasing their potential, it’s evident that soft robotics holds a pivotal role in future advancements.

Despite facing challenges such as durability and control mechanisms, research continues to push boundaries. Experts believe that overcoming these hurdles will unlock even more possibilities for robots designed with flexibility in mind.

As we look ahead, soft robotics promises exciting developments across various sectors. Its ability to mimic natural movement while adapting to different tasks makes it an invaluable tool for tomorrow’s innovations. With ongoing research and experimentation in this field, there’s no telling what new heights adaptive robots can reach next.